Choosing the right plastic injection molding machine is crucial for efficient production. According to industry expert John Smith, “Selecting the appropriate machine can make or break your project.” This underscores the importance of understanding your specific needs.

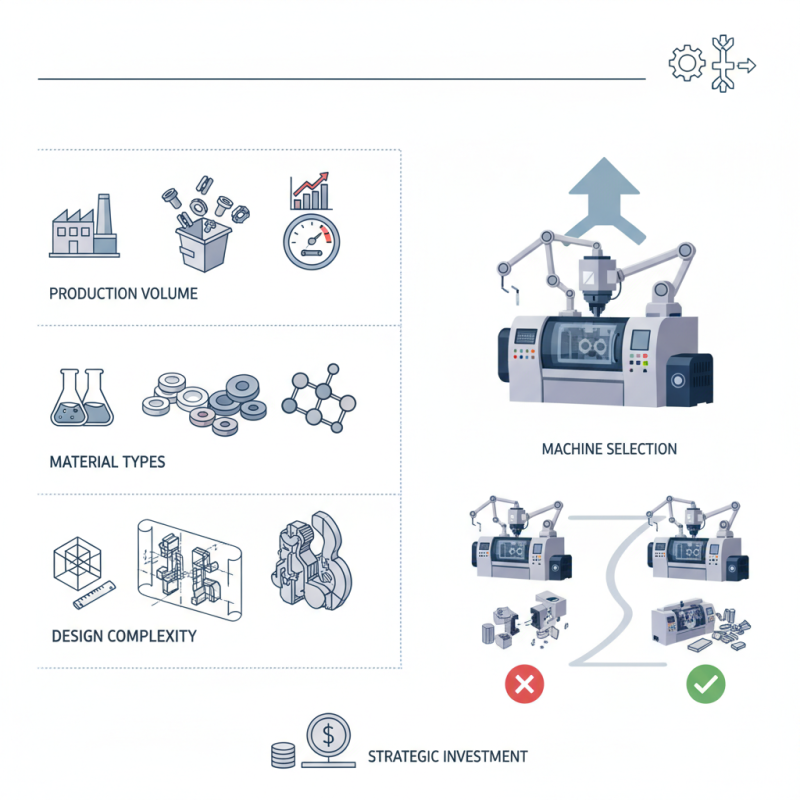

Many factors influence the selection of a plastic injection molding machine. Factors such as production volume, material types, and complexity of designs are essential. It’s not always straightforward. Some may prioritize cost over quality, which can lead to long-term challenges. Inadequate machines can result in higher waste and reduced efficiency.

Reflect on your production requirements. Analyze what features are necessary for your success. Remember, investing in the right plastic injection molding machine is not just a choice—it's a strategic decision.

Choosing the right plastic injection molding machine begins with understanding your production requirements. Your needs can vary based on factors like production volume, part complexity, and material types. In this way, clarity is crucial.

Evaluate your production volume. High-volume production may warrant a machine with greater speed and capacity. Conversely, low-volume needs could be met with smaller, more affordable options. Consider automation features, too. They can enhance productivity but may increase initial costs.

Tip: Identify the materials you intend to use. Different materials require different processing conditions. This can affect machine selection and mold design. Be aware of the nuances. For instance, some materials may lead to mold wear, affecting durability over time.

Lastly, consider part complexity. Intricate designs require precise machines. If you're producing simple parts, that’s one thing, but complex shapes could lead to unforeseen difficulties. Make sure to analyze prototype tests to adapt your selection based on real-world performance. Finding the right balance can take time and multiple trials.

This chart illustrates the production volume capabilities of different sizes of plastic injection molding machines. Small machines can produce up to 100 units per hour, while extra-large machines can reach up to 2000 units per hour. This information can help you choose the right machine based on your production needs.

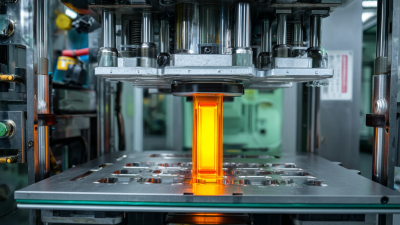

When selecting a plastic injection molding machine, focusing on key features is crucial. Understanding the clamping force is vital. This force determines the machine’s ability to hold the mold under pressure. Machines typically range from 20 to 5,000 tons, depending on the application. A report by Grand View Research indicates the global plastic injection molding market was valued at $254 billion in 2021. The right clamping force can influence product quality significantly.

Another important feature is the injection unit design. The screw design affects the melting and mixing of plastic materials. For instance, a machine with a larger screw diameter can handle higher viscosity resins. Data from MarketsandMarkets shows a growing demand for customized solutions in this sector. However, the trade-off is complexity and potential maintenance challenges. The machine's cycle time is also a consideration, as quicker cycles can lead to higher productivity, but may impact part quality.

Lastly, the control system plays a role in precision. Advanced control systems allow for real-time monitoring and adjustments. Automation levels can vary widely, which can complicate the selection. A balance between ease of use and advanced features must be achieved. Manufacturers often struggle to find this balance, leading to inefficiencies or frustration in operation. Thus, understanding these features is essential for making an informed choice in selecting a plastic injection molding machine.

| Feature | Importance | Recommended Specification | Typical Range |

|---|---|---|---|

| Clamping Force | Essential for holding the mold in place during injection | 150 - 400 tons | 100 - 600 tons |

| Injection Speed | Affects cycle time and part quality | 50 - 200 mm/s | 30 - 250 mm/s |

| Shot Size | Determines the maximum volume of plastic that can be injected | 500 - 1200 cm³ | 200 - 1500 cm³ |

| Mold Size | Must fit within the machine's specifications | 500 x 500 mm | 300 x 300 mm to 800 x 800 mm |

| Machine Type | Influences cost, efficiency, and operation | Hydraulic, Electric, Hybrid | Varies by application |

When selecting a plastic injection molding machine, consider the type that best fits your needs:

hydraulic,

electric, or

hybrid.

Hydraulic machines use oil for power. They are known for their strong clamping force and can handle large, complex molds.

However, they consume more energy and can be less precise than their electric counterparts.

The noise level can also be high. You may need to contemplate whether those factors align with your operational requirements.

Electric machines are quieter and more energy-efficient. They offer

precise control of the injection process.

This can lead to consistent part quality.

However, they may not suit heavy-duty applications since their clamping force is lower compared to hydraulic models.

The higher initial investment can be daunting, but savings from energy bills might offset the costs over time. Remember to weigh these aspects carefully during your decision-making.

Hybrid machines combine the strengths of both types. They often deliver

better energy efficiency while maintaining power.

Nonetheless, the complexity of their components may lead to

increased maintenance challenges.

Choosing the right machine is not always clear-cut. Each option has its pros and cons.

Reflect on your production needs and future goals to make a well-informed choice.

When considering plastic injection molding machines, budget is crucial. The initial cost can range from $10,000 to $250,000, depending on the machine's size and capabilities. According to industry reports, the average small to medium-sized machine costs about $50,000. However, hidden costs often arise. Maintenance, energy consumption, and tooling can add 30-50% more to the total investment.

Energy efficiency is another factor. An energy-efficient machine may have a higher upfront cost but will save money in the long run. Reports suggest that these machines can reduce energy costs by 20-30%. It's vital to assess the long-term operational savings against initial expenses. Many companies overlook this, leading to higher operating costs.

Don't just focus on purchase price. Training staff can also be an expense to consider. Many businesses underestimate the time and resources needed for proper training. This oversight can impact production efficiency. Additionally, think about your production needs. A machine that seems affordable might not meet your output requirements. That could mean investing in another machine sooner than expected.

Researching manufacturers and after-sales support is crucial when selecting a plastic injection molding machine. Many factors influence your decision. The quality of the machine, its reliability, and long-term maintenance can greatly impact your production efficiency. According to industry reports, about 30% of machine downtime is attributed to poor after-sales support and inadequate training. This statistic emphasizes the importance of choosing a manufacturer with strong support systems.

Tips: Look for companies that offer comprehensive training programs. Ensure they provide technical support and readily available parts. You don't want to face delays due to ineffective service.

When assessing manufacturers, consider their reputation in the market. Customer reviews and case studies can provide insight into their reliability. A manufacturer with a proven track record may reduce your operational risks. However, an attractive price doesn't always mean quality. Exercise caution with cost-cutting options as they may lack durability. Quality should always take precedence over price.

Tips: Compare multiple manufacturers before deciding. Gathering different quotes helps identify the best value. Researching also opens opportunities to learn from others’ experiences. Don't rush this process; doing so might lead to poor choices.