The efficiency and innovation of plastic injection molding machines are pivotal in the manufacturing sector, where precision and speed are paramount. According to a recent report by MarketsandMarkets, the global plastic injection molding machine market is projected to reach USD 12.3 billion by 2025, driven by the increasing demand for lightweight and durable plastic parts across various industries. This technology not only enhances production capabilities but also significantly reduces material waste, aligning with sustainable manufacturing trends. As businesses continue to seek competitive advantages, understanding the nuances of plastic injection molding machine efficiency will be critical for optimizing operations and fostering innovation. The integration of advanced automation and smart manufacturing practices is set to further revolutionize the industry, making it essential for manufacturers to stay informed about emerging technologies and best practices in plastic injection molding.

The efficiency and innovation of plastic injection molding machines are pivotal in the manufacturing sector, where precision and speed are paramount. According to a recent report by MarketsandMarkets, the global plastic injection molding machine market is projected to reach USD 12.3 billion by 2025, driven by the increasing demand for lightweight and durable plastic parts across various industries. This technology not only enhances production capabilities but also significantly reduces material waste, aligning with sustainable manufacturing trends. As businesses continue to seek competitive advantages, understanding the nuances of plastic injection molding machine efficiency will be critical for optimizing operations and fostering innovation. The integration of advanced automation and smart manufacturing practices is set to further revolutionize the industry, making it essential for manufacturers to stay informed about emerging technologies and best practices in plastic injection molding.

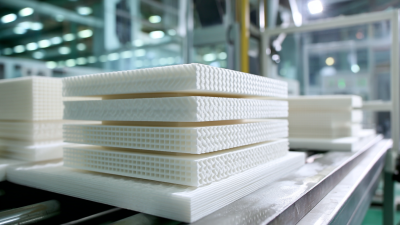

The efficiency of plastic injection molding machines is influenced by several key factors that manufacturers must consider to optimize their operations. First, machine design and technology play a crucial role in determining the precision and speed of the injection process. Innovations such as advanced control systems and energy-efficient components can significantly enhance the overall performance of these machines. Additionally, the choice of materials and the molding process parameters, such as temperature and pressure, directly impact the quality of the final product and the efficiency of production.

The efficiency of plastic injection molding machines is influenced by several key factors that manufacturers must consider to optimize their operations. First, machine design and technology play a crucial role in determining the precision and speed of the injection process. Innovations such as advanced control systems and energy-efficient components can significantly enhance the overall performance of these machines. Additionally, the choice of materials and the molding process parameters, such as temperature and pressure, directly impact the quality of the final product and the efficiency of production.

Another important factor is the maintenance and upkeep of the machinery. Regular maintenance schedules help in preventing breakdowns and ensuring that the machines operate at peak efficiency. Furthermore, the training and skill level of the workforce can also influence machine performance. A well-trained operator can better manage the molding process and troubleshoot issues, leading to reduced cycle times and lower production costs. As the global micro injection molding machine market continues to grow, focusing on these efficiency factors will be vital for manufacturers aiming to stay competitive.

Innovative techniques for enhancing

injection molding performance are crucial for manufacturers seeking to optimize

production efficiency and product quality. One approach is the integration of

advanced automation technologies, such as

robotics and

AI-driven systems. These technologies streamline the molding process by minimizing cycle times, improving precision, and reducing manual intervention.

For instance, the use of collaborative robots (cobots) in conjunction with injection molding machines allows for greater flexibility and consistency, enabling

manufacturers to produce complex parts with minimal variations.

Another key innovation is the implementation of

smart monitoring systems that utilize

IoT sensors to gather real-time data on machine performance. This data-driven approach enables

predictive maintenance, which can significantly reduce unexpected downtimes and enhance overall productivity.

By continuously tracking parameters such as

temperature,

pressure, and

cycle time, manufacturers can swiftly detect anomalies and make informed adjustments. Additionally, experimenting with

advanced materials and

additives can further enhance the properties of molded products, leading to

lighter,

stronger, and more

sustainable end products that meet evolving market demands.

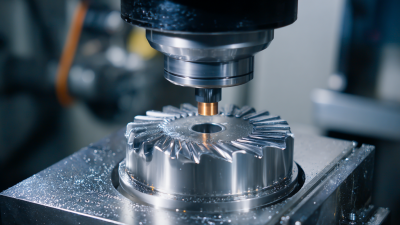

In the ever-evolving landscape of manufacturing, the efficiency of plastic injection molding machines stands as a crucial factor in optimizing production processes. Evaluating energy consumption is paramount, as energy costs can account for up to 30% of total operational expenses in injection molding facilities. According to a report by the Association for Plastic Recyclers, advanced injection molding technologies can reduce energy consumption by as much as 40%, leading to significant cost savings for manufacturers. By integrating energy-efficient machinery and process optimizations, companies can not only decrease their environmental footprint but also enhance their bottom line.

Moreover, innovation in injection molding techniques, such as the introduction of servo-driven systems, can markedly improve efficiency. These systems often have faster cycle times and higher precision, resulting in less material waste and reduced energy use. A recent study from the American Society of Plastics Engineers indicates that transitioning to servo-powered machines can yield energy savings of nearly 50% compared to conventional hydraulic systems. This shift not only promotes sustainability but also supports manufacturers in staying competitive within the market by reducing production costs and increasing throughput.

The realm of plastic injection molding is experiencing a significant transformation, driven by advancements in automation and smart technologies. Recent industry reports indicate that the global injection molding machine market is projected to reach $12.8 billion by 2026, reflecting a compound annual growth rate (CAGR) of 3.8% from 2021. This growth is largely attributed to the increasing adoption of Industry 4.0 technologies, which integrate IoT (Internet of Things) devices into the manufacturing process. Such innovations enable real-time monitoring of machinery performance, predictive maintenance, and enhanced production efficiency.

Automation in injection molding not only reduces labor costs but also minimizes human error, leading to higher product quality and consistency. According to a report by MarketsandMarkets, the implementation of automation in manufacturing processes could enhance production efficiency by as much as 30%. Furthermore, smart technologies, such as AI-driven analytics, are now capable of optimizing machine settings dynamically, greatly reducing downtime. As manufacturers continue to embrace these technological advancements, the injection molding industry stands to not only increase output but also achieve greater sustainability by minimizing waste and energy consumption.

This chart illustrates the efficiency improvements in plastic injection molding machines from 2015 to 2023. The data reflects advances in automation and smart technologies that have contributed to better production rates and reduced downtime.

Regular maintenance of plastic injection molding machines is crucial for ensuring their efficiency and longevity. A well-maintained machine can significantly reduce downtime and improve product quality. One of the best practices is to establish a routine inspection schedule that includes checking hydraulic fluids, lubricating moving parts, and cleaning filter systems. Moreover, keeping an eye on the temperature and pressure settings can help identify potential issues before they escalate.

**Tips:** Always document maintenance activities and any changes made to the machine settings. This record can be useful for troubleshooting future problems and optimizing performance.

Troubleshooting efficiency issues involves a systematic approach to identifying the root causes of problems. Common issues might include inconsistent cycle times or poor part quality. Employing techniques such as cause-and-effect analysis can aid in pinpointing specific factors contributing to inefficiencies. It is also beneficial to train operators on recognizing early signs of machine malfunction, ensuring they can act promptly.

**Tips:** Encourage open communication between maintenance teams and machine operators. Regular feedback can uncover operational challenges and foster innovative solutions for improving efficiency.

| Machine Model | Cycle Time (seconds) | Energy Consumption (kWh) | Production Rate (units/hour) | Maintenance Frequency (weeks) | Downtime (hours/month) |

|---|---|---|---|---|---|

| Model A | 30 | 15 | 120 | 4 | 2 |

| Model B | 28 | 12 | 135 | 6 | 1.5 |

| Model C | 32 | 14 | 115 | 5 | 3 |

| Model D | 27 | 11 | 150 | 3 | 0.5 |