In the realm of product design, vacuum forming has emerged as a transformative technique that allows designers to craft intricate shapes with precision and efficiency. As we delve into the top 10 vacuum forming techniques for superior product design, it's essential to highlight the profound impact this method has on modern manufacturing. According to Dr. James Elliott, a renowned expert in the field of vacuum forming, "The art of vacuum forming not only enhances the aesthetic appeal of a product but also significantly improves its functionality."

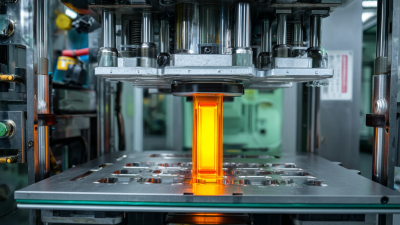

This innovative process, which uses pressure differentials to shape thermoplastic materials over molds, is a cornerstone of many industries, including automotive, packaging, and consumer electronics. By exploring the nuances of vacuum forming, designers can unlock new possibilities, pushing the boundaries of creativity while ensuring that products meet both form and function. In the following sections, we will discuss various techniques that can elevate product design, highlighting how vacuum forming continues to be a pivotal element in the design and manufacturing landscape.

As we look toward 2025 and beyond, understanding these techniques will prove vital for professionals aiming to stay at the forefront of design innovation. By harnessing the unique advantages of vacuum forming, designers can create superior products that not only meet market demands but also captivate consumers with their design quality.

Vacuum forming has emerged as a key technique in modern product design, offering numerous benefits that enhance the creative process. According to the International Association of Plastics Distribution, the vacuum forming market is projected to grow significantly, driven by increasing demand for customized and highly aesthetic products. This technique allows designers to create intricate shapes and structures that would be difficult or impossible to achieve with traditional methods. With the ability to produce lightweight yet durable components, vacuum forming empowers brands to explore innovative designs while maintaining functionality.

The integration of vacuum forming into product design not only meets aesthetic demands but also aligns with sustainability goals. A report by the Plastic Industry Association highlights that vacuum forming minimizes material waste, providing an eco-friendly alternative in product development. Furthermore, its rapid prototyping capabilities significantly reduce time-to-market, allowing companies to respond swiftly to consumer trends. As brands embrace these advantages, vacuum forming solidifies its position as an essential methodology in delivering superior product designs that resonate with modern consumers' preferences.

| Technique | Description | Applications | Benefits |

|---|---|---|---|

| Standard Vacuum Forming | Basic technique using heated plastic sheets. | Displays, Packaging | Cost-effective, quick setup. |

| Thermoforming | Heating sheets to form complex shapes. | Automotive, Medical Devices | Higher detail and precision. |

| Pressure Forming | Utilizing air pressure to enhance shaping. | Consumer Electronics | Improved texture and thickness. |

| Drape Forming | Hanging plastic sheets over molds. | Creative Art and Design | Artistic flexibility. |

| Twin Sheet Forming | Two sheets fused during forming. | Packaging, Containers | Enhanced strength and insulation. |

| Blow Forming | Air is blown into heated material. | Bottles, Jars | Fast production, lightweight products. |

| Vacuum Tube Forming | Utilizing tubes for uniform shapes. | Industrial Components | Consistency in design and dimensions. |

| In-Mold Decoration | Decoration during the forming process. | Consumer Products, Toys | Reduced production steps. |

| Recyclable Vacuum Forming | Using recyclable materials in forming. | Sustainable Products | Environmentally friendly. |

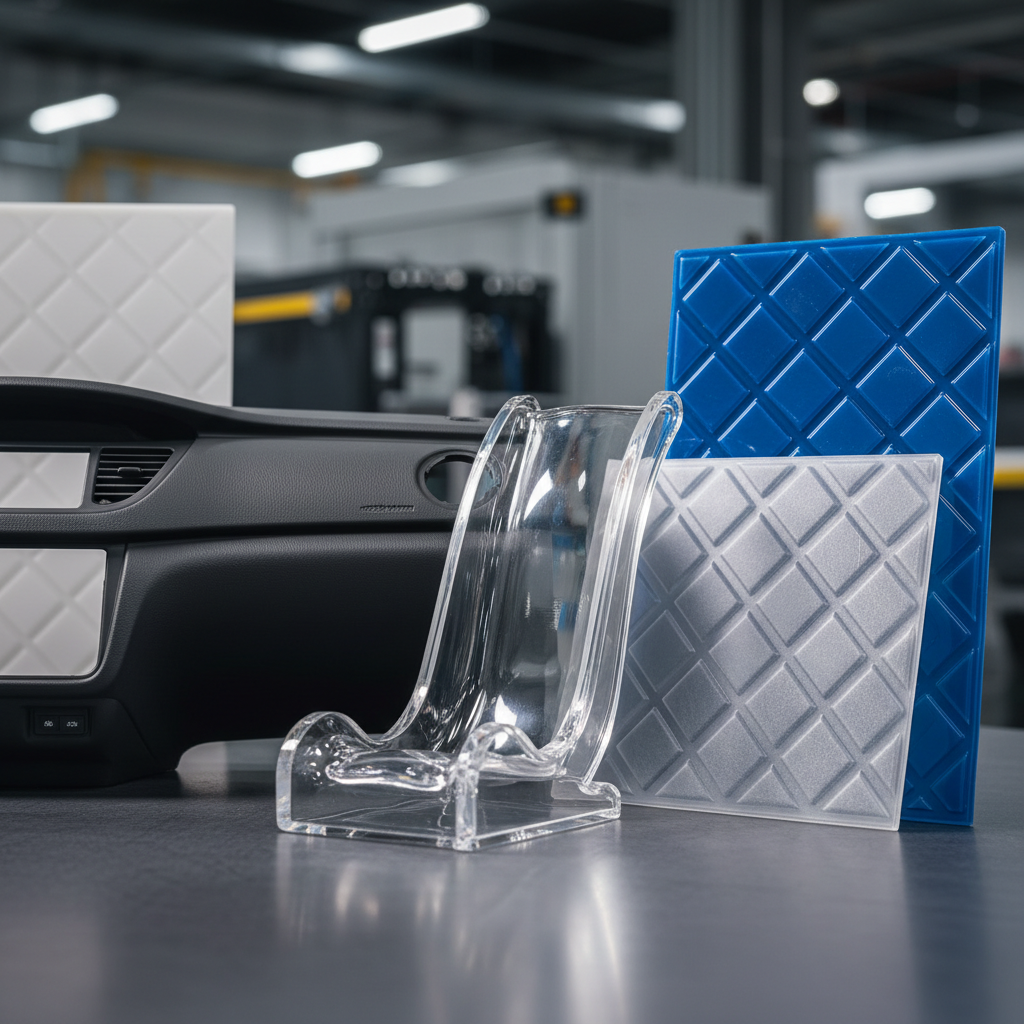

Vacuum forming is a versatile manufacturing process that significantly enhances product aesthetics through a variety of techniques. One essential technique involves the careful selection of materials. Utilizing high-quality thermoplastics not only influences the visual appeal of the final product but also allows for intricate designs and textures that can elevate the overall aesthetic. Materials like acrylic and polycarbonate can provide clarity and brilliance, while textured finishes can add depth and tactile quality, drawing in consumers and enhancing their experience.

Another important vacuum forming technique is the application of advanced design software. By leveraging CAD and 3D modeling tools, designers can produce intricate and precise mold designs that improve both the functionality and beauty of products. This precision allows for unique shapes and custom features that make products stand out in the market. Furthermore, the ability to simulate various finishes and colors digitally enables designers to visualize the end result, ensuring that the aesthetic qualities align perfectly with the brand's vision before committing to production.

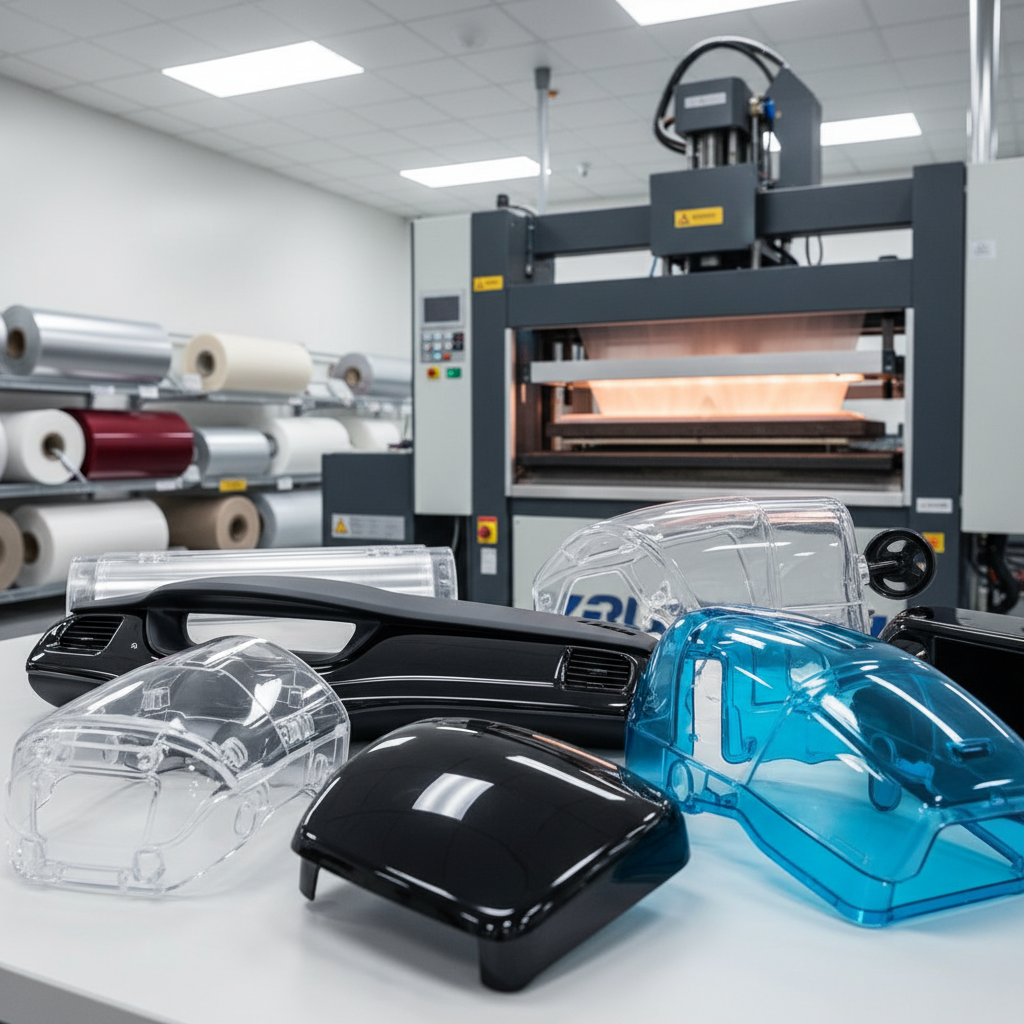

Innovative materials play a crucial role in enhancing the effectiveness of vacuum forming applications. The use of thermoplastic materials like ABS, polycarbonate, and PETG has gained immense popularity because of their excellent moldability and durability. These materials are not only lightweight but also provide great impact resistance and thermal stability, making them suitable for various industries, from automotive components to consumer products. Their flexibility in design allows for intricate and detailed shapes, which can lead to superior product aesthetics.

Moreover, the incorporation of advanced composite materials such as fiberglass-reinforced plastics can significantly enhance the strength and performance of vacuum-formed products. These composites offer superior rigidity and resistance to environmental stress, which is essential for products exposed to harsh conditions. In addition to composites, emerging bio-based polymers are making a mark by providing sustainable options for manufacturers. These materials not only reduce the carbon footprint but also cater to the growing consumer demand for eco-friendly products. By leveraging these innovative materials, designers can push the boundaries of vacuum forming, resulting in high-quality, efficient, and environmentally responsible product designs.

When it comes to vacuum forming, precision is critical for achieving superior product design. One of the key considerations is material selection. Each thermoplastic material offers unique properties, such as flexibility, strength, and temperature resistance, which can significantly influence the final product's quality. Choosing the right thickness and type of material ensures that the formed parts meet the desired specifications and functional requirements.

Another essential factor is the design of the mold. A well-designed mold facilitates better airflow and enables uniform heat distribution, reducing the risk of defects such as warping or incomplete forming. It's crucial to account for the draft angle and surface texture in the mold design, as these elements directly affect how the material will release from the mold post-forming. Additionally, maintaining precise control over heating times and vacuum levels during the forming process ensures that the material achieves optimal pliability, leading to a greater level of detail and accuracy in the final product.

This bar chart illustrates the effectiveness of various vacuum forming techniques based on precision, material versatility, and production speed.

Vacuum forming is a widely used technique in various industries due to its versatility and cost-effectiveness. A notable application can be seen in the automotive sector, where vacuum-formed parts, such as dashboards and interior panels, contribute to weight reduction without compromising strength. According to a recent report by Market Research Future, the global automotive vacuum forming market is expected to grow at a CAGR of 4.5% from 2021 to 2027, driven by the increasing demand for lightweight materials to enhance fuel efficiency.

Another successful application of vacuum forming is in the packaging industry. For example, leading brands have adopted this technique to create custom clamshell packaging that not only protects products but also enhances their shelf appeal. A study from Smithers Pira indicates that the global rigid plastic packaging market, including vacuum-formed packaging, is projected to reach $407 billion by 2024. This trend highlights the importance of vacuum forming in developing sustainable packaging solutions that align with the growing consumer demand for eco-friendly materials.