In the constantly evolving landscape of CNC machining, enhancing precision and efficiency is vital for manufacturers striving to maintain a competitive edge. Industry expert John Smith, a renowned figure in CNC machining technology, emphasizes, "The key to successful CNC machining lies not just in the machinery, but in the understanding and application of best practices throughout the production process." This insight highlights the significance of adopting strategic methods to optimize machining outcomes.

As CNC machining continues to advance, operators are faced with the challenge of maximizing both output and accuracy. By implementing essential tips and techniques, businesses can significantly improve their production processes and achieve higher standards of quality. This article delves into ten crucial CNC machining tips—designed to empower operators and engineers alike, ensuring that they not only meet but exceed their operational goals. With a focus on practical applications, these recommendations will serve as a vital guide for enhancing efficiency and precision in today's fast-paced manufacturing environment.

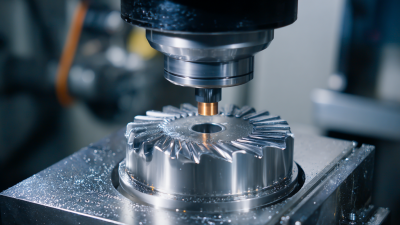

When optimizing CNC machining for improved precision and efficiency, one critical factor to consider is the helix angle of the mill cutter. A larger helix angle can significantly influence the balance between axial and radial forces. As the helix angle increases, the axial force on the end mill tends to rise, while radial force and vibration generally decrease. This shift can result in a smoother cutting action and enhanced tool life, as the reduced vibrations lead to less wear on the cutting edges and improved surface finish on the workpiece.

To maximize tool life further, it is essential to select the appropriate feed rates and spindle speeds tailored to the specific material and machining operation. A balance must be struck to prevent excessive heat build-up, which can lead to premature tool failure. Additionally, employing effective coolant strategies can help maintain optimal operating temperatures and further extend tool longevity. By carefully considering these factors, manufacturers can enhance their production processes and achieve higher precision while minimizing downtime caused by tool-related issues.

To optimize machine setup is crucial for enhancing precision in CNC machining. According to a study by the National Institute of Standards and Technology (NIST), improperly set up machines can lead to discrepancies in dimensional accuracy, often resulting in up to 30% of production waste. To mitigate this issue, it's essential to conduct a thorough pre-setup analysis, which includes calibrating tools and aligning workpieces accurately. By investing time in these key steps, manufacturers can significantly reduce errors, thereby increasing both productivity and product quality.

Moreover, utilizing advanced software solutions for simulation and toolpath optimization can further streamline the setup process. The 2021 Manufacturing Technology Trends Report highlights that 75% of companies that implemented digital twin technologies in their CNC operations saw an improvement in setup times by more than 20%. This not only enhances operational efficiency but also allows engineers to experiment with various machining strategies in a virtual environment before actual production. Emphasizing these critical setup steps can lead to superior outcomes, maximizing the overall precision of the CNC machining process.

| Tip Number | CNC Machining Tip | Benefits | Implementation Steps |

|---|---|---|---|

| 1 | Regular Maintenance | Increased machine lifespan | Schedule routine checks every month |

| 2 | Use Quality Tools | Improved cut quality | Invest in high-grade cutting tools |

| 3 | Optimize Feed Rate | Enhanced machining efficiency | Adjust feed rate according to material |

| 4 | Tool Path Optimization | Reduced cycle times | Analyze and plan tool paths carefully |

| 5 | Implement Advanced CAM Software | Precision planning | Select software with robust features |

| 6 | Use Proper Work Fixtures | Increased part stability | Invest in custom fixtures |

| 7 | Regular Tool Inspection | Improved machining accuracy | Inspect tools before each shift |

| 8 | Maintain a Clean Work Environment | Reduced contamination | Implement cleaning schedules |

| 9 | Monitor Machine Performance | Identify and respond to issues quickly | Use performance metrics for analysis |

| 10 | Educate and Train Employees | Enhanced skill set and awareness | Conduct regular training sessions |

Implementing advanced software solutions is crucial for enhancing precision in CNC machining processes. As industries increasingly adopt automation, tools that leverage robotics and digital manufacturing technologies can dramatically improve accuracy and efficiency. For instance, the global CNC machine market is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, indicating a CAGR of 9.9%. This growth underscores the importance of integrating sophisticated software systems that facilitate seamless operation and optimize production workflows.

In addition to software, automated calibration systems are transforming the landscape of manufacturing accuracy. These systems reduce reliance on manual processes and enhance the precision of measurements, which is essential for maintaining high standards in production. For example, reports suggest that companies implementing intelligent calibration solutions see significant improvements in their manufacturing processes. Gerdau's application of AI technologies demonstrated a remarkable increase in accuracy to 95% in product analysis, significantly lowering costs by 65%. Such advancements not only boost operational efficiency but also enhance overall competitiveness in a rapidly evolving market.

Regular maintenance is crucial for ensuring optimal performance and longevity in CNC machining. A well-maintained machine will not only produce higher quality components but will also reduce unexpected downtime and costly repairs. Start by implementing a daily checklist that includes inspecting tools for wear, checking fluid levels, and ensuring that all safety mechanisms are functioning correctly. Weekly, perform a more thorough inspection, including cleaning the machine's interior, checking for dust and debris in critical areas, and confirming that all mechanical components are lubricated as required.

Additionally, don't overlook the importance of software updates and calibration. Keeping the CNC machine's software up-to-date ensures that you benefit from the latest technology and improvements in efficiency. Regularly calibrate the machine based on the manufacturer's guidelines to maintain accuracy in production parts. This focus on routine maintenance not only enhances the precision of operations but also promotes a smoother workflow, making your overall production process more efficient and reliable.

The choice of materials in CNC machining plays a crucial role in determining the outcome of both precision and efficiency. Utilizing high-quality materials minimizes defects and ensures that machined parts meet stringent tolerance requirements. Materials that are robust and stable under varying temperatures and pressures contribute to a more consistent machining process. For instance, investing in premium-grade metals such as titanium or high-carbon steel can lead to superior finishes and durability, ultimately reducing the need for rework.

In addition to material quality, understanding the properties of the chosen materials is key to optimizing the machining process. Different materials respond uniquely to machining tools and cutting techniques. For example, softer materials may require different feeder rates compared to harder ones. Properly matching the machining parameters to the specific material can reduce tool wear and enhance productivity. As such, selecting the right materials and tailoring the machining process accordingly can significantly improve both the efficiency of production and the precision of the final product.