In today's competitive manufacturing landscape, optimizing your injection molding process is crucial for achieving significant efficiency gains and maximizing profitability. As companies strive to enhance production capabilities while minimizing waste, understanding the intricacies of the injection molding process becomes paramount. This blog will explore seven actionable tips designed to boost your operational efficiency by up to 30 percent.

From streamlining material selection to refining machine settings, each strategy targets key areas that impact productivity. By implementing these recommendations, manufacturers can not only improve their workflow but also strengthen their position in the market, ensuring they remain at the forefront of innovation and sustainability in the injection molding industry. Join us as we delve into effective techniques that can transform your production processes and drive long-term success.

Optimizing injection molding processes is crucial for enhancing productivity and efficiency. One effective approach is identifying key performance indicators (KPIs) that can help manufacturers monitor and refine their operations. Research indicates that integrating methodologies like Six Sigma can lead to significant improvements, with studies showing a 30% increase in efficiency across various manufacturing systems. This is particularly relevant for small and medium enterprises reliant on make-to-order production, where adapting processes to meet specific customer demands is vital.

Moreover, employing techniques such as the Taguchi method and Analysis of Variance (ANOVA) can help in optimizing injection molding parameters. These methodologies support the reduction of defects, such as warpage and weight inconsistencies, thereby improving the overall quality of the finished products. For instance, advancements in managing defects like sink marks and shrinkage have been shown to result in better product consistency and reduced waste. By focusing on these specialized parameters and implementing data-driven strategies, manufacturers can track performance metrics effectively and drive continuous improvements within their injection molding processes.

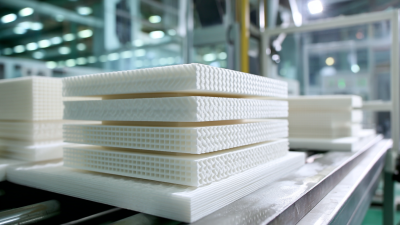

Selecting the right materials is crucial in streamlining the injection molding process to enhance production efficiency. Different materials can significantly affect the quality of the final product, the speed of the injection process, and the overall sustainability of the production method. By carefully analyzing specific project requirements, manufacturers can identify the most suitable plastics that not only meet performance criteria but also optimize cycle times and reduce waste. This thorough selection process allows for improved consistency and productivity in the manufacturing line.

Additionally, leveraging advanced materials, such as bio-based or recycled plastics, can lead to a more sustainable operation without compromising on quality. Such choices often reduce processing time due to their thermal properties, further improving efficiency. Educating the team about the characteristics of various materials and how they interact with the injection molding process can lead to better decision-making. Ultimately, by focusing on strategic material selection, companies can achieve a more effective injection molding process, setting the stage for substantial improvements in production efficiency.

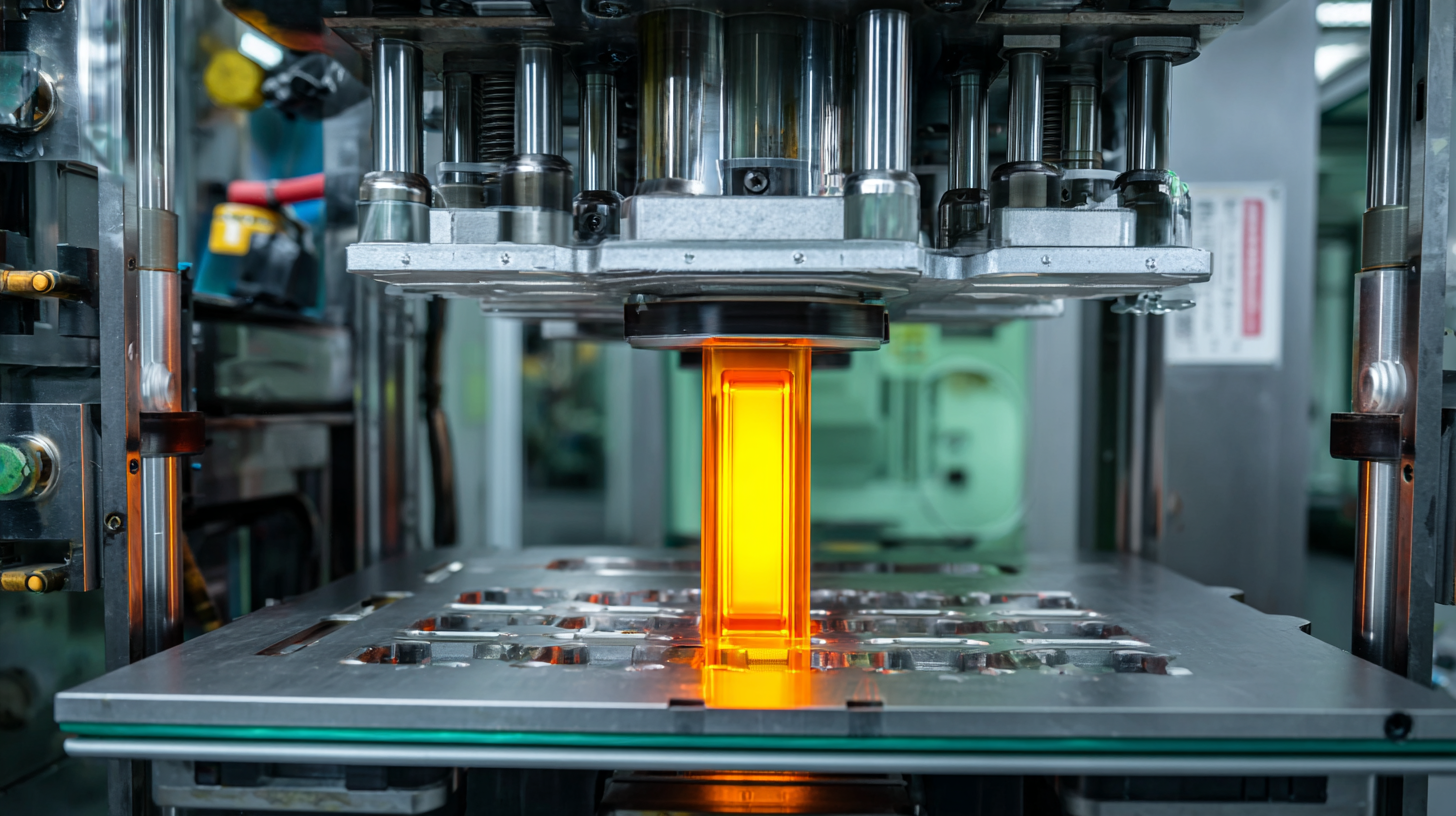

In the competitive landscape of manufacturing, implementing advanced technology for increased automation in injection molding can significantly enhance efficiency. Automation not only minimizes human error but also accelerates production cycles. By integrating robotic systems and intelligent machinery, manufacturers can streamline operations, ensuring consistent quality and faster turnaround times. These technologies facilitate precise control over mold filling, cooling times, and even post-processing operations, allowing for a more optimized and effective production process.

Moreover, adopting real-time monitoring tools can further boost automation. These systems provide critical insights into machine performance, quality metrics, and production rates. By employing predictive maintenance strategies, businesses can prevent unexpected downtimes and enhance overall equipment effectiveness. The synergy between automation and data analytics empowers manufacturers to make informed decisions, adapt to market demands swiftly, and maintain a competitive edge. Embracing this advanced technological landscape in injection molding is a crucial step toward achieving significant efficiency boosts and long-term sustainability.

In the competitive landscape of the injection molding industry, optimizing processes for efficiency is crucial. A 30% boost in productivity can be achieved through regular maintenance best practices, which significantly reduce downtime and improve output. Research indicates that companies focusing on preventive maintenance can increase their operational efficiency and minimize unexpected failures, leading to an overall enhancement in production rates.

Moreover, the global market for shredders is projected to grow from $2.616 billion in 2024 to $4.70556 billion by 2032, reflecting a compound annual growth rate of 7.6%. This growth underscores the increasing importance of efficient waste management solutions in manufacturing processes. As more industries prioritize sustainability and cost-effectiveness, integrating advanced maintenance protocols in injection molding can set businesses apart, ensuring they remain competitive in a rapidly evolving market. By committing to systematic upkeep, manufacturers can not only mitigate operational risks but also capitalize on emerging market opportunities.

In the competitive landscape of manufacturing, training your team for optimal performance in injection molding operations is essential to enhancing efficiency and productivity. According to a report by the Association for Manufacturing Technology, companies that invest in workforce training can boost their operational efficiency by up to 25%. This significant improvement often results from a better understanding of machine calibration, process parameters, and troubleshooting techniques among operators.

Moreover, a recent study from the Society of Plastics Engineers indicates that nearly 70% of production issues stem from operator error and insufficient training. By focusing on comprehensive training programs that highlight best practices in injection molding, organizations can not only reduce defect rates but also decrease cycle times, resulting in a potential 30% increase in overall efficiency. Implementing regular workshops and hands-on training sessions not only empowers your workforce but also fosters a culture of continuous improvement, which is crucial in today’s fast-paced manufacturing environment.